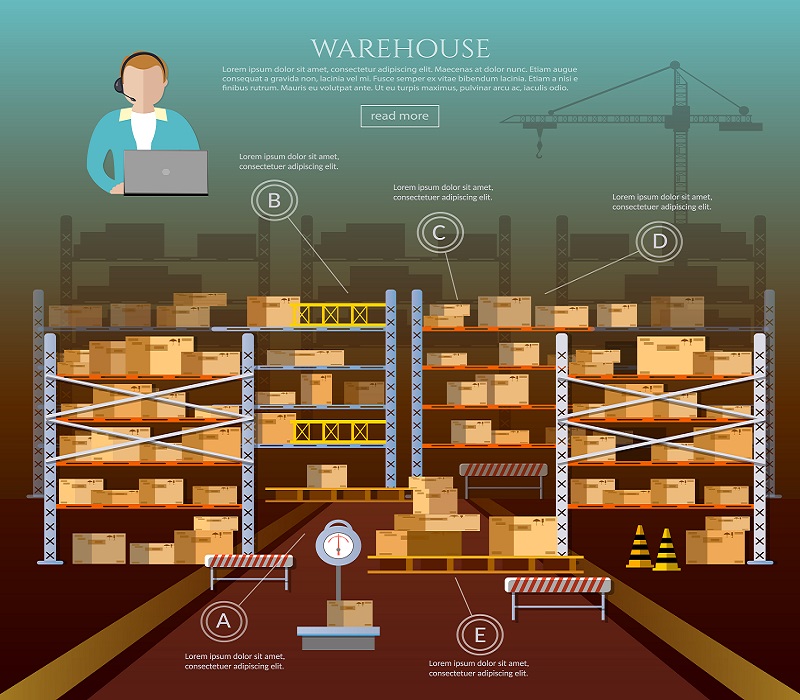

Warehouse racking ensures the smooth and easy functioning of the warehouse and helps in easy storage of warehouse goods. The overall effectiveness of pallet racking depends on a lot of factors such as:

- Facility layout

- The breadth of the aisles

- The demand for the products

- Proper use of established racking system etc

Warehouse operators can consider the following suggestions for the proper functioning of the warehouse racking:

#1. Pre-planning: Every warehouse company needs to plan their layout properly. The basic floor plan of the warehouse should give the information about the placement of the things such as the site of receiving and shipping, the location of staging areas, manager’s deck, employee zone, the position of the pallet racks etc. If all these are not planned from before, things will look very clumsy and congested.

#2. Make a proper budget: You need to make a budget to decide the amount of money that will be spent in the installation as well as maintenance of warehouse racking. You should not look for a cheaper racking but should also look into the quality. If you are looking for a better storage option, you should consider purchasing pallet flow or push back racking systems.

#3. Try to increase the vertical space in the warehouse: If you are looking forward to using the entire space of the warehouse you should try to set up vertical storage units. If you think that your warehouse is not big enough to store a lot of goods and thinking of relocating, before taking such a decision, try to build up the warehouse by increasing the spaces intelligently. This will save a lot of money which will be spent on shifting the goods to a new location and also avoid expansion cost as well. You can also store the goods by keeping smaller items in view and the larger ones safe from any kind of damage or destruction by using the full space of your warehouse.

#4. You should ignore the previous obstructions in order to design a layout: The initial layout should be drawn in a way ignoring the existing obstruction and columns of the warehouse. After the whole layout is completed, the obstructions can be incorporated adjusting your efficient layout in a small amount to make room for the obstructions. Floor space obstructions will always be present. Still, there can be problems like the columns may look clumsy and hardware may cluster in one place. Thus an effecting shelving layout system should be flexible.

#5. Storage efficiency should be calculated: The amount of space required to store a single pallet rack is known as storage efficiency. If you know the proper storage efficiency of your warehouse, installing a pallet rack will not be a difficult task. The area of a warehouse is represented in square feet whereas the amount of space used up by a pallet is represented in the cubic height of the whole building. Thus, proper warehouse racking uses up only a little space of the warehouse and are good options for storing goods conveniently.

#6. Know the proper arrangement of the racks: If you arrange the racks intelligently, the warehouse will not only look bigger but will also allow storage of more goods. You should try to arrange the racks in long rows instead of shorter ones to avail greater space. Arranging the racks towards the walls is also not a good option as that may reduce the efficiency of the storage. Another action which should be omitted is creating an L-shaped storage system as they are quite tough to navigate.

Thus, if you follow the above steps, warehouse racking will not be a difficult task.